Gauteng Peanut Butter Machine In South Africa Johannesburg

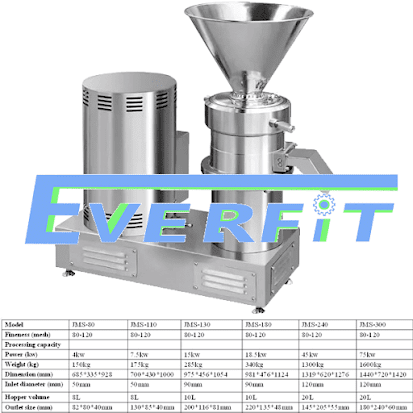

Peanut butter is made from high-quality peanuts and other raw materials. The finished product is hard and tough, with a strong aroma of fried peanuts. High-quality peanut butter is generally light beige, delicate in quality, rich in aroma and free of impurities. At present, the machines for making peanut butter on the market generally use: peanut butter grinding machine . This equipment is driven by a motor, which drives rotating teeth (or called rotors) and matching fixed teeth (or called stators). The two grinding bodies are composed of There is a small gap that can be adjusted. When the material passes through this gap, due to the high-speed rotation of the rotor (its linear speed is generally 13-40m/s), the speed of the material attached to the rotor surface is the largest, while the speed of the material attached to the stator surface is zero. This produces a sharp velocity gradient, so that the material is subjected to physical effects such as strong shear, friction, high-frequen...